Aluminum Honeycomb Panel

Classification :

Aluminum Veneer

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

PRODUCT DETAILS

The weiaht of Sun seven color aluminum honevcomb panel is less than 1 / 3 of that of aluminum veneer, which is verylight, large in layout size, high in fiatness and never deformed; there are many and simple installation methods; it has goodtoughness and high strength, which can be used for celling design with high load: it has good sound insulation and heatinsulation performance.

FEATURES:

High strength, large stifness, flexion resistance, compressive resistance, sunshine colorful industry adhering tothe aviation honeycomb complex force technology, developed applicable to the construction, aviation, transportation,navigation has a high load of aluminum honeycomb plate.

lts load requirements are completely in accordance with thewind pressure value of 3000-10000pa design, processing and production. its high strength performance is suitable forall areas of the building.

Planeness: the planeness deviation of yangguang colorful series aluminum honeycomb plate is strictly controlledwithin the national standard.

Sound insulation, heat insulation, moisture-proof: the honeycomb structure of sunbeam colorful aluminumhoneycomb plate forms a unit room, the air does not convection, with good heat insulation performance, and aluminumhoneycomb plate is a complex structure, with good sound insulation effect.

Light weight: the weight per square meter is 4.5-8kg, (the thickness of aluminum honeycomb plate is different, theweight is different) is the same specification of the aluminum plate 1/5, 1/10 of the steel plate.Good aseismic and buffering performance.

Non-toxic, green environmental protection: passed the 1SO9001 international quality system certification1S014001 international environmental management system certification.

The aluminum veneer curtain wall uses high -quality high -strength aluminum alloy plates. Its common thickness is 1.5, 2.0, 2.5, 3.0mm, the model is 3003, and the status is H24. The maximum size of conventional materials is 1220mmx2440mm. Its structure is mainly composed of panels, reinforcement and angle code. The corner code can be bent and stamped by the panel, or the corner code can be taken on the small side of the panel. Strengthening the welding screws after the tendon and the surface of the surface to make it a solid whole, which greatly enhances the strength and rigidity of the aluminum veneer wall, and ensures the flatness and wind and earthquake resistance in long -term use. If you need to sound insulation, you can install the sound insulation insulation material of the inner installation of the inner side of the aluminum plate.

The surface of the aluminum veneer curtain wall is generally processed before chromium, and then carbon spraying is used. Fluorocarbon coating surface paint and envious polyethylene ethylene resin (KANAR500) -The is divided into two, three or four paint. Fluorocarbon coating has corrosion resistance and weather resistance. It can resist acid rain, salt mist, and various air pollutants. It has good cooling and cold resistance. It can resist strong ultraviolet rays. long. Our factory chooses high -quality fluorocarbon coatings from companies such as PPG, DNT, AKZO, NIPPON and other companies in the world -renowned air -carbon coating manufacturer. It is widely selected or provided by the manufacturer.

Features

1. Light weight, good steel, high strength 3.0mm thick aluminum plate weigh 8kg per square plate, tensile strength 100-280N/mm2

2. Good durability and corrosion resistance. PVDF gas carbon paint with Kynar-500 and Hylur500 as the base material can be used for 25 years without fading.

3. Good process. The spraying process is used first, and the aluminum plate can be processed into a variety of complex geometric shapes such as plane, arc and sphere.

4. Uniform coating and diverse colors. Advanced static spraying technology makes the paint between the paint and aluminum plate evenly, with a variety of colors, and the choice of space is large.

5. It is not easy to defile, which is convenient for cleaning and maintenance. The non -stickability of the fluorine coating membrane makes it difficult to attach pollutants on the surface, and it is more good.

6. Installation construction is convenient and fast. The aluminum plate is formed in the factory, and the construction site does not need to be cut. It can be fixed on the skeleton

7, recyclable and reuse, which is beneficial to environmental protection. Aluminum plates can be recovered 100%, different from decorative materials such as glass, stone, ceramics, aluminum -plastic plates, etc., and the recovery is high.

Application field

The scope of application of aluminum veneer is widely reflected in the following aspects. In terms of building facades, aluminum veneer is often used for exterior wall decoration of large buildings such as high -end commercial buildings, office buildings, hotels, etc. Its aesthetic and durable characteristics can enhance the overall image and taste of the building and attract more attention. In terms of interior decoration, aluminum veneer also has a wide range of applications, such as ceilings, walls, partitions, etc. Aluminum veneer can not only provide colorful decorative effects, but also has the advantages of fire prevention, moisture -proof, easy cleaning, etc., making it an ideal choice for indoor decoration.

Case display

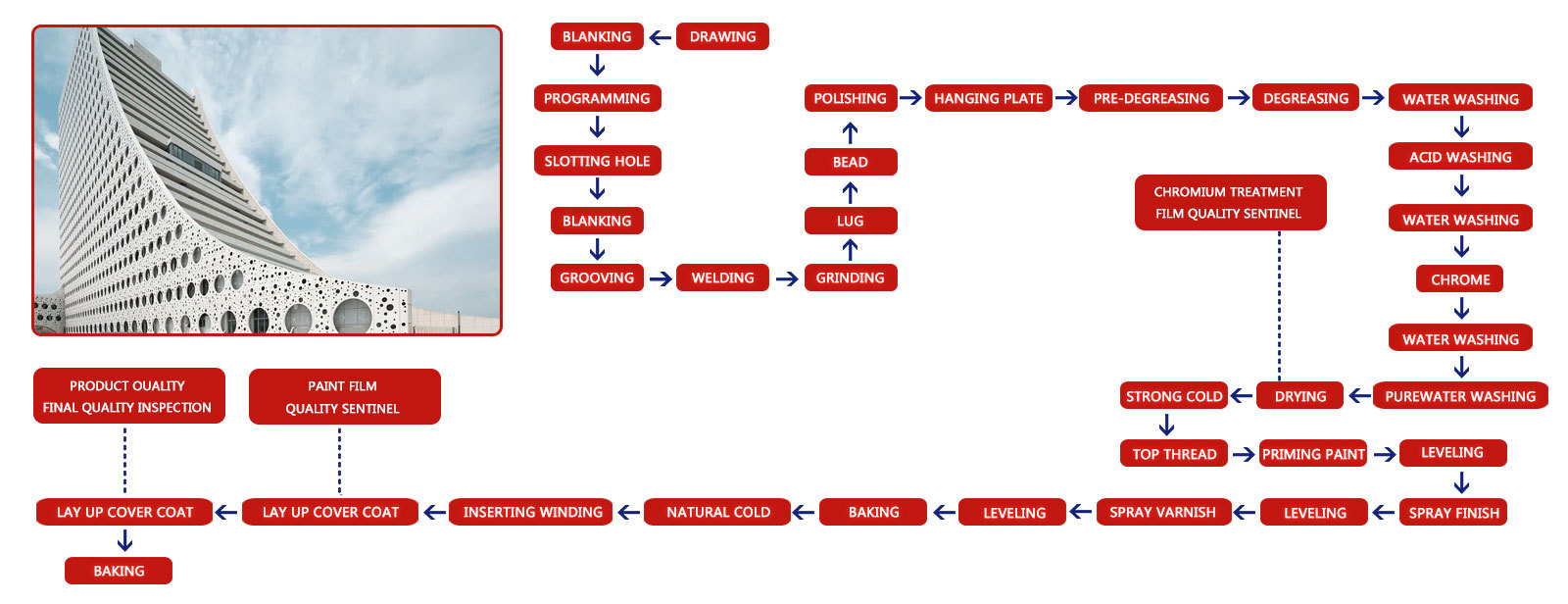

Production process

RELATED PRODUCTS

GET A FREE QUOTE